Special Operations / By CW4 Jason Slusse: How can technology and data analytics improve mission readiness and reduce risk? We are entering an era where predictive data analytics, through Artificial Intelligence (AI), can improve Aviation sustainment. When it comes to data analytics, an organization cannot expect to have valuable, visualized information from their data without doing some work up front.

ALL GRAPHICS COURTESY U.S. ARMY SPECIAL OPERATIONS AVIATION COMMAND

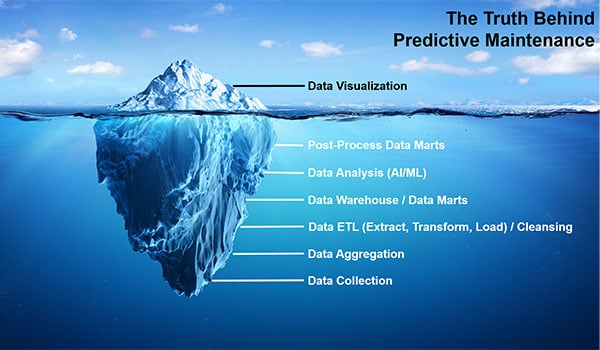

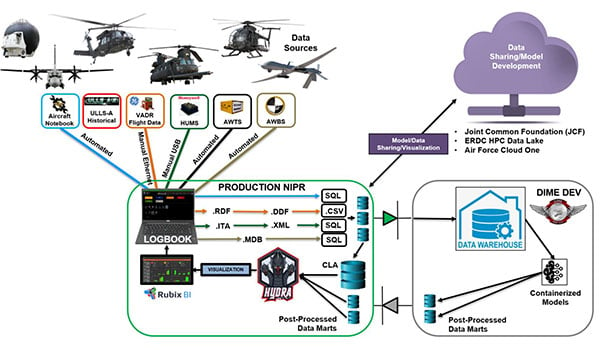

What we see in the data analytics dashboards are just the “tip of the iceberg” in the process and it only depicts the visualization piece of this puzzle. Identifying data sources, collection, aggregation, preparation and analytics are “below the water line” actions required to achieve success in visualization. Additionally, it is difficult to identify a specific problem to use AI technologies to solve unless descriptive analytics are used to give an organization a clear picture of what is taking place.

Aviation sustainment data analytics relies on three key ingredients: data, data professionals and domain expertise. Data includes various sources such as time-series, vibration sensors, and human input. Data professionals are data engineers, data scientists, and software developers. Domain expertise incorporates data analysts and aviation maintenance subject matter experts. The 160th Special Operations Aviation Regiment (Airborne) (160th SOAR) has a successful descriptive analytics program because they have all three key ingredients through an on-site team.

DIME

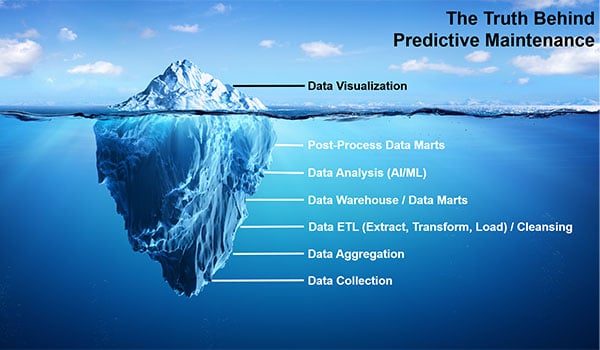

In 2011, the 160th SOAR Digital Integrated Maintenance Environment (DIME) was established to answer a simple question; “What does it cost to fly a helicopter?” Depending on who responded the answer would be different. The lack of a single full spectrum answer pointed out a clear requirement for data analytics. The DIME identifies data sources, collects and aggregates data, and makes that data available within a Common Landing Area (CLA) database. It serves as the authoritative source of truth for the 160th SOAR and its industry partners.

Using business intelligence (BI) tools to conduct descriptive analytics allows the 160th SOAR to “see themselves” through the data and identify areas for improvement. For example, a review of aircraft utilization versus availability exposed an existing inefficiency with contract maintenance. The majority of CONUS flights were conducted during the same hours that maintainers were at work. Adjusting the maintenance hours around flight schedules so that maintainers were at work when aircraft were on ground improved maintenance efficiency. This example seems obvious, but it was not clear until data was analyzed and visualized. Additionally, through BI tools, the 160th SOAR was able to analyze Aircraft Notebook data and, through ties to work unit codes (WUC), identify the top money, mission and maintenance drivers for each aircraft type.

PMx Mission Initiative

To minimize unscheduled maintenance across the Department of Defense, the Joint Artificial Intelligence Center (JAIC) stood up the Predictive Maintenance (PMx) Mission Initiative in 2018. During the initial PMx kickoff meeting, the 160th SOAR was able to present a very specific problem that AI technologies could help solve. This was done by referencing live data to analyze the top money, mission and maintenance drivers for the MH-60M helicopter fleet. The GE YT-706 engine was the number one driver for all three categories at the time. As a result, the JAIC utilized hot start shutdowns as the first focus for PMx AI model development. This led to the formation of the SOCOM Incubator effort, a partnership between the JAIC, Carnegie Mellon University (CMU), the Army AI Task Force and 160th SOAR, to jump-start PMx initiatives with the intent of sharing products and lessons learned to benefit the DOD as a whole. The first outcome of the SOCOM Incubator was the Engine Health Model (EHM), developed by CMU data scientists against 160th SOAR Voice and Data Recorder (VADR) data. This machine-learning model was delivered via python script to the 160th SOAR where DIME software developers containerized the model and deployed it on the network.

The 160th SOAR is working to operationalize this EHM to make informed, operational and maintenance decisions on scheduling maintenance that would have been unscheduled. Having the ability to decide when to perform maintenance based on pending failures will reduce mission aborts, aircraft downtime and costs while giving commanders greater operational flexibility.

As part of operationalizing the EHM, and to provide timely information in an edge environment with limited transport for data backhaul, DIME developers built the Model at the Edge (MaTE) Kit. The MaTE Kit consists of a laptop computer loaded with the VADR download tool, containerized EHM, and a web-based visualization of AI predictions for operational users. The intent of the MaTE Kit is to provide the user on the ground with an “all in one” tool to interface the aircraft, download data, process and store data, and visualize the output of the EHM.

Dirty Data

The most significant lesson learned from analyzing maintenance data was the existence of “dirty data” which are inaccuracies within the data whether caused by human or hardware error. An example of human injected “dirty data” that negatively effects AI capabilities is that many of the WUC’s in Aircraft Notebook are either generic or fell into the wrong functional group all together. To maximize data accuracy, the 160th SOAR DIME developed a Natural Language Processing (NLP) tool to analyze free text entries of fault narratives to correct the WUC in a two-step process. The first step is to determine the correct functional group WUC (2 digits), followed by the second step predicting the specific WUC (up to 8 digits). This corrected data is then fed back into the Composite Threat List live view, creating a more accurate snapshot of top money, mission and maintenance drivers.

Although this article references the PMx SOCOM Incubator effort, most of the data sources and tools used by the 160th SOAR are Army common. All data flows through an Army common Aircraft Notebook software and aircraft logbook. These efforts are completely scalable and the intent is to make these solutions and lessons learned available DOD-wide through the JAIC partnership.

Through the power of data analytics, commanders have an additional tool to increase availability, efficiency and decrease costs and maintenance burden. However, adopting these technologies may take some change in the current culture. Organizations should embrace the “red” areas of what their data is telling them and not try to avoid it. Data-focused organizations should continuously ask, “What data do I have? What data do I need? What data do I want? And why don’t I have the data that I need and want?”

Forward thinking will help get this culture into a preemptive mode, identifying and tackling problems that haven’t even occurred yet. With the upcoming influx of predictive models, there will also be tools to assist commanders in decision making based off the output of those models. This type of prescriptive analysis will help commanders choose the best course of action based on risk, but as with any of these tools, humans provide judgement.

CW4 Jason Slusser is the maintenance technology officer with the U.S. Army Special Operations Aviation Command (Airborne) Aviation Maintenance Support Office located at Fort Campbell, KY.