Maintenance/Sustainment / By COL Shawn T. Prickett and Mr. James P. Snyder: Modernization and the future force is a top priority for the Army, and there is currently a buzz about the future of Army Aviation. The discussion of Future Vertical Lift (FVL) capabilities and capacity is shaping the way future warfare may be conducted. FVL will provide a currently unattainable range and station time, proving combatant commanders flexibility and decision space during future operations. Future sustainment concepts will provide increased reliability, reduced maintenance per flight hour, ensuring Army Aviation’s unparalleled support to the warfighter. With all of the benefits that our future capabilities offer, the enterprise cannot lose focus on the fact that the current fleet of aircraft will still be a key combat multiplier in the future. The age of our current fleet and the operational demand placed on these aircraft, our maintenance efforts, policy, and data processes must be focused and adapted to meet those demands.

U.S. Soldiers with D Company, 1st Battalion, 3rd Aviation Regiment (Attack Reconnaissance), 12th Combat Aviation Brigade, conduct routine maintenance on an AH-64 Apache helicopter on Aug. 17, 2018, at Katterbach Army Airfield in Ansbach, Germany./U.S. ARMY PHOTO BY CHARLES ROSEMOND

As a branch, we pride ourselves on quality maintenance practices in support of our fleet. The professionalism of our maintenance teams has consistently been of the highest quality, even with the increasing demands we place on the aircraft and our maintainers. By design, the multiple maintenance echelons provide for the safest and most reliable fleet available, and our logistics professionals ensure replacement components and services are fully sourced and at the point of need.

As our current fleet of aircraft continues to experience increased flying hour tempo, heavier loads and more austere environments than ever before, our maintenance practices must meet those demands. As the operational continuum becomes more complex and the reality that our current fleet will remain with us through as late as 2050, we must develop innovative processes to ensure the safety of our crews and the reliability of the aircraft for these demands. A key element of future sustainment processes are major maintenance events, and specifically, Reset of aircraft.

Reset Program

The Reset program was incorporated into our sustainment concept over 15 years ago to help offset the environments and tempo that Army Aviation was required to operate in during the Global War on Terrorism. Reset provided a method to revitalize those aircraft operating in that environment and ensure their safety and reliability for the upcoming training and/or deployment demands. The program has proven to be very successful and has met or exceeded the goal for which it was established. Even with the success the Reset program has given us in terms of fleet management over the years, there are challenges that we must address in order to leverage the program and sustain our fleet for the future. Worldwide operations require increased training opportunities to ensure our crews are the best qualified in the world and we continue to provide aircraft into the fleet. This changing dynamic requires we reexamine how/when aircraft are inducted into major maintenance events to ensure our current fleet’s viability through 2050.

The requirements for aircraft reset have not evolved to reflect the decrease in operational tempo in the combat environs. Time vs. condition based maintenance is proving inefficient and costly in the long term. We have experienced many instances where this requirement just doesn’t make sense and the same methodology is not the best way to focus limited resources on the aircraft that need it most. An AH-64E with only 500 hours would likely not require Reset just because it deployed to Afghanistan for 9 months. We should consider prioritizing aircraft reset for those that have been stressed in these demanding environments, not just that they were deployed. Because we are limiting Reset to those aircraft deployed to contingency operations, there are funding challenges should we apply Reset, fleet-wide. With funding tied to Overseas Contingency Operations, expanding fleet-wide Reset will come with a bill that will require programming concurrence from other Army stakeholders. Lastly, the predictability of the current model enables appropriate planning at the unit level and by those conducting aircraft Reset. Using ‘on-condition’ Reset for the fleet will require a significant level of synchronization and timing across the enterprise. These challenges are not unsurmountable, but the real challenge is determining how to implement this concept.

SDST

Last year, GEN Abrams, then the Army Forces Command Commander asked the enterprise, “Is there a better way to determine which aircraft require Reset?” Since then, AMCOM, together with AMRDEC, and HQDA have been developing a tool to better evaluate which aircraft require major maintenance. The tool, known as the Sustainment Decision Support Tool (SDST) takes the full history of the aircraft into account. The tool is managed by the AMCOM G-3(M) Continued Airworthiness and Materiel Readiness Division. Weighted factors outline the current overall condition of the aircraft to provide a health score which provides visibility and predictability to determine resources, transfers and potential shortfalls.

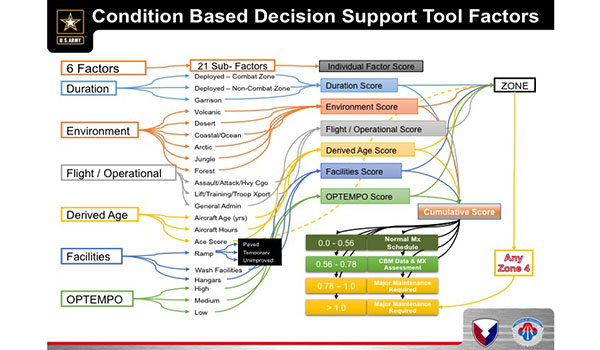

The process currently takes into account six factors and twenty one sub factors of the aircraft history. Factors include:

- Utilization – Deployed-Combat Zone; Deployed-Non-Combat Zone; Garrison

- Environment – Volcanic; Desert; Coastal/Ocean; Arctic; Jungle; Forest

- Flight/Operations – Assault/Attack/Heavy Cargo; Lift/Training/Troop Transport; General Admin

- n Derived Age – Aircraft Age (years); Aircraft Hours; Ace Score

- Facilities – Ramp (paved, temporary, unimproved); Wash Facilities (time without); Hangars (time without)

- OPTEMPO- High; Medium; Low

These factors provide a baseline understanding of aircraft utilization and primary factors that have historically driven maintenance actions. Each of these factors must be intimately researched to capture the most accurate data possible. Once collected and verified it is input into the SDST and the weighted factors are taken into account. In return, they provide a total health score for that aircraft. Not only will the SDST provide the current health score, it can also be used to forecast health scores using historical data.

While the tool isn’t perfect, it has proven to be a large step forward in understanding the multiple factors that affect our fleet. The goal is to assess every aircraft in the Army inventory utilizing this tool, in order to gain better insight into trends affecting the fleet. Using the SDST gives us the opportunity to provide more predictive maintenance schedules and resource requirements to the Department of the Army. The SDST allows us to assess fleets that have historically been left out of major maintenance planning, like the training fleet at Fort Rucker. When you consider their OPTEMPO, it is evident that we must accomplish major maintenance on the training fleet to ensure availability. While they fly heavy mission cycles, they have not been considered for major maintenance because they haven’t deployed. The SDST will provide a level standard across the enterprise and enable situational understanding, by tail number and order of merit list, on which aircraft need induction into major maintenance.

The goal is to embed the SDST into the digital logbook, providing a constant health status of that aircraft, leveraging that data to better perform fleet management. The future forecast process will be available for PC, BAMO and the commander to help guide decisions, mitigate risk, and to optimize aircraft utilization and maintenance planning. This information will feed back through the readiness reporting process for assessment and planning at the enterprise level. Implementation of this tool, changes to policy, with adequate funding, will enable a view of our fleet for the tactical commander and the strategic leader. These tools and this condition based approach will ensure our current fleet of aircraft continue to provide safe, outstanding mission support now and into the future.

COL Shawn T. Prickett is the chief of staff for the U.S. Army Aviation and Missile Life Cycle Management Command (AMCOM); and Mr. James P. Snyder is the Condition Based Maintenance (+) lead for AMCOM G-3/5 Continued Airworthiness and Materiel Readiness (G-3M) both at Redstone Arsenal, AL.