AMRDEC Tech Talk / By Mr. Mike Vourcos: The Airframe Condition Evaluation (ACE) program provides a method for capturing data for the U.S. Army to supplement identification of aircraft candidates for depot-level maintenance in accordance with Army Regulation (AR) 750-1.

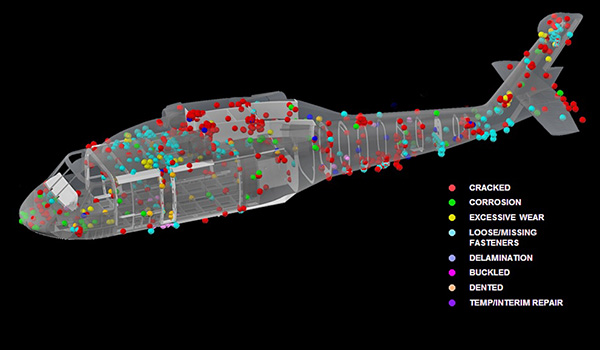

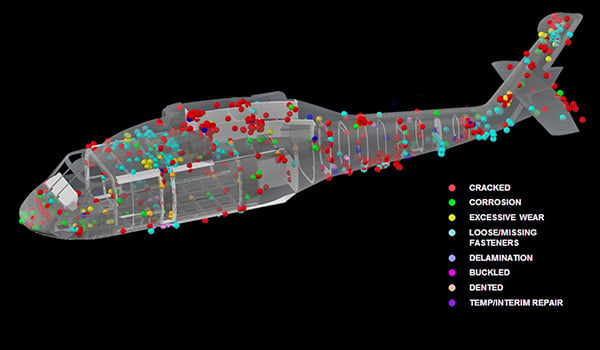

ACE defects for the 1,432 H-60 aircraft evaluated in 2016. The color coded points represent defect locations and type of defect. / AMRDEC AED GRAPHIC

The Corrosion Prevention and Control Evaluation (CPCE) is an integral part of the ACE program and provides additional data for corrosion prevention initiatives. Aircraft are evaluated annually by aircraft ACE teams which results in the generation of a profile index, or score, for each tail number. An occurrence of a fault/discrepancy at an indication location times the weight factor for that indicator location adds to the score. Indicator weights are based upon the critical nature at that indicator location. The highest scored aircraft are the ones that are in most need of depot maintenance.

Every year, engineers in the Aviation Engineering Directorate (AED) Maintenance Engineering Division analyze the ACE data and publish an annual technical report for Army UH-60, AH-64, and CH-47 rotary aircraft. This ACE Technical Review provides the overall structural condition assessment of the Apache, Chinook, and Black Hawk fleets based upon comparative engineering analysis of ACE and CPCE data, indicators, and system condition codes. The report is provided to respective fleet managers in support of depot-level maintenance induction candidate selection. The report includes a list of the high scored aircraft recommended for depot level overhaul, “Top 10 Significant Maintenance Issues” list emphasizing major structural and CPCE areas affected, and discussion of structural hotspots that are unique to each aircraft configuration (Figure 1).

CPCE data collected during the ACE process are analyzed and used to determine corrosion issues being experienced in the fleet. This analysis leads to improved maintenance practices that minimize corrosion and mitigate future corrosion failures. The CPCE data are also used in future design efforts by identifying airframe areas that need improved corrosion resistant materials. While CPCE data are not used to determine depot candidacy, they are used to supplement ACE with critical fleet health information.

Identifying Trends

Year-to-year analysis of ACE data provides an assessment of current fleet condition and developing trends for maintenance/sustainment consideration. For example, AED recently provided essential ACE data to AMCOM to assist in evaluating the ongoing requirements for the aircraft RESET program.

ACE is crucial in determining aircraft condition when extending deployment tours and deciding which aircraft will be “stay behind equipment” (SBE). The Army Aviation Assessment Team is a variant of ACE and provides critical data to help evaluate potential impacts to airworthiness and mission readiness of SBE candidates. By utilizing ACE data, AED can compare and assess the structural condition of deployed aircraft vs. home station aircraft to supplement SBE decisions.

Note, whether or not an individual aircraft (by tail number) is evaluated in any given year does not, in itself, present an airworthiness issue. The airworthiness of each aircraft on a “day-to-day” basis is maintained through the requisite scheduled inspections and maintenance performed by aviation maintainers in accordance with prescribed aircraft maintenance technical manuals.

An Eye to the Future

In addition to the ACE Technical Review, ACE data is provided to Corpus Christi Army Depot, AMCOM and Aviation program management offices to aid them in considering and forecasting future structural improvements. ACE and CPCE data are also used to shape the future of U.S. Army aircraft maintenance practices, depot aircraft overhaul workload, system design improvements (UH-60M, CH-47F & AH-64E), and Future Vertical Lift (FVL) aircraft design and maintenance improvements.

AED does utilize the fleet-wide data generated by the ACE program to maintain overall cognizance of the fleet condition and provide engineering solutions that have a significant impact on continuing airworthiness. If this flow of data were ever to be interrupted, AED’s ability to maintain this cognizance and anticipate future airworthiness or readiness problems related to structural degradation would be severely impacted.

Mr. Mike Vourcos is an aerospace engineer in the Maintenance Engineering Division of the Aviation Engineering Directorate of the U.S. Army Aviation and Missile Research, Development, and Engineering Center. He is located at Corpus Christi Army Depot, TX.