128th Aviation Brigade / By SSG Joshua Hankins: In the continuing quest to find better and faster ways to repair and return aircraft to full mission capable status while offering a stronger, lighter, and cheaper alternative to traditional sheet metal materials, the Army has fully embraced advanced composite structures.

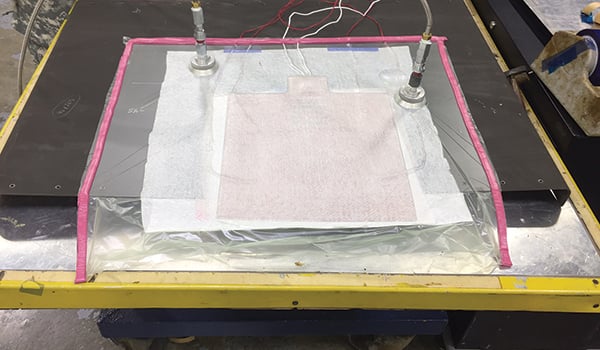

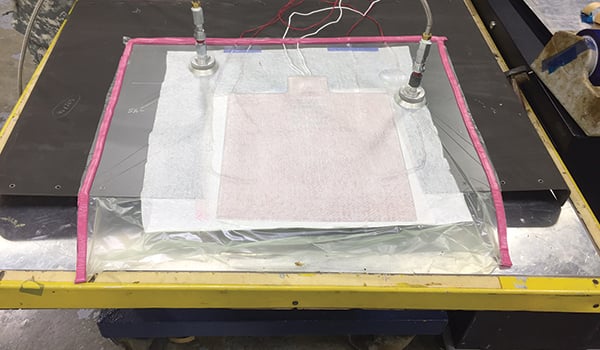

Students get hands on experience with the vacuum bag required for advanced composite repairs. / 128th AVN BDE PHOTO

Recognizing the advantages of advanced composites in specific aircraft components such as the horizontal stabilators on the UH-60M and the AH-64E, we proceeded without a clear concept or capability to repair in the field short of returning to the original equipment manufacturer (OEM) or depot level repair. This “cart before the horse” scenario overwhelmed both the supply system and reduced readiness until we had a clear way ahead to repair these extremely expensive components in the field.

Adjusting the POI

Aircraft Structural Repairers (MOS 15G) are subject matter experts in sheet metal repair, their skills are finely developed to accommodate tight tolerances and they proudly demonstrate their ability to repair practically any flaw in an aircraft sheet metal skin to keep aircraft flying. These skills however do not translate into repairing carbon fiber, fiberglass, or aramid, thus creating the need for changes in technical training and education.

To affect the pivot to composites, the 128th Aviation Brigade recently implemented changes to Advanced Individual Training (AIT) and Advanced Leader Courses (ALC) technical track to facilitate the training of advanced composite repair to the Army’s 15G entry-level repairs and technical inspectors.

Beginning in FY 17, the Basic Aircraft Structural Repair course (15G10) will add 64 hours of instruction in advanced composites. Initial Entry Training (IET) Students in training to become aircraft structural repairers now participate in a course that includes a six-step repair certifying each student to perform proper repairs to aircraft advanced composite components. Additionally, students gain a basic knowledge of advanced composite structures such as manufacturing parts, safety in composites, repair joints, different fabrics and adhesives, and vacuum bagging techniques.

The instruction they receive has a heavy focus on the theory behind advanced composites and the repair of the advanced composite structure. This instruction will include lessons that will train students to remove liquid from sandwich construction, create alternative vacuum bags, prepare different types of repair joints, and repair partial thickness damage of a laminate.

ALC 15G30

The ALC course (15G30) underwent corresponding changes. Many of today’s Aircraft Structural Repairer NCOs attended the 15G10 course prior to 2010, therefore it is necessary for them to receive formal training on advanced composites that was not previously included in their technical military education. The 30-level course now offers hands-on training that will give 15G supervisors the knowledge to perform advanced composite repairs at their unit, supervise Soldiers performing these repairs, and inspect repairs once completed.

The redesign affords supervisors the opportunity to perform hands-on practical exercises including machining repair joints and repairing carbon fiber aircraft panel edge bands. Previously, they were limited to just repairing a Kevlar component with minor damage. Supervisors in the other MOSs are introduced to advanced composites in order to give them the knowledge of how repairs are correctly performed. Included in the instruction are equipment needed, materials used in repairs, and inspection techniques. As technical inspectors, these NCOs will be expected to certify that repairs are performed properly in accordance with the specific aircraft technical manuals.

In FY17, the Army will produce proficient 10 level advanced composite repairers. AIT graduates will have a deeper understanding of composite structures and more experience with creating vacuum bags to fit any repair situation they may encounter. Additionally, supervisors going through ALC will now have the ability to perform and inspect these repairs to ensure the quality of aircraft and the proper on-the-job training of subordinates.

This training not only saves money in reducing the number of components that have to be replaced, but it also gives the Army flexibility and depth to operate and conduct self-sustaining aviation operations wherever Army Aviation is called.

SSG Joshua Hankins is an instructor/writer with Company C, 2nd Battalion, 210th Aviation Regiment, 128th Aviation Brigade at Joint Base Langley-Eustis, VA.